Views: 0 Author: Site Editor Publish Time: 2025-09-08 Origin: Site

You need a dependable induction heater control board for your work. These boards have smart temperature control, live monitoring, and strong safety. JONSON gives you solutions that help industries using electromagnetic induction heating. With advanced control technology, you get steady power and fast reaction.

You get help from diagnostics and fault finding, which lower downtime.

Remote control and data logging let you watch and change your process easily.

Heating profiles make sure your results stay steady and work well.

Pick a control board that has smart temperature control. This helps keep heating the same every time.

Find safety features like overheat protection. These keep your equipment and team safe.

Choose a board with real-time monitoring. It helps you spot problems early and stop long breaks.

Get models with good connectivity. This makes it easy to connect to your factory network.

Think about energy efficiency features. They help save money and are better for the environment.

You need steady power to keep your induction heating system working well. Newer induction heater control boards use smart ways to manage power. High-performance systems often use these methods:

Thyristor power control with full-wave AC drive changes the main voltage.

Three-phase variacs and motorized voltage regulators give classic control.

Two-part tank coil designs help improve magnetic coupling and efficiency.

Solid-state devices like SCR, IGBT, and MOSFET make medium and radio frequency currents.

JONSON’s induction heater control board is special because it uses these new solutions for steady and efficient power. The table below shows how JONSON matches up with industry standards:

Feature | Description |

|---|---|

Efficiency | Advanced control solutions help make industrial heating more efficient. |

Stability | Works smoothly with high-frequency induction heaters for steady power. |

Energy Optimization | Smart temperature control and live monitoring give the best performance. |

Safety Features | Extra safety features help the system work safely in many jobs. |

Cost Reduction | Helps companies save money while keeping good heating results. |

Good temperature control is important for quality and safety. You get this control with smart algorithms and sensors. Most induction heating control boards use PID control algorithms. These work with thermocouples or RTDs to check the temperature. The control panel changes the heat to keep the temperature where you want it.

You get:

Quick reaction to temperature changes.

Steady heating for even results.

Less chance of getting too hot or too cold.

JONSON’s temperature control keeps your process steady, even if the workload changes. This means you can trust your system to give the right heat every time.

Safety features keep your equipment and team safe. You need these systems to stop overheating and electrical problems. Good induction heater control boards include:

Regular checks of system temperature to stop overheating.

Good airflow around the equipment to let heat out.

Strong electrical connections to prevent problems.

Cooling system checks to keep things safe.

Power input checks to stay within safe limits.

These safety features help stop damage to the power supply and heating parts. They also keep your workspace safe from things like bent parts or runaway heat. JONSON’s control panel has advanced safety features, so you can work without worry.

You want to find problems before they stop your work. Good diagnostics and monitoring help you do this. JONSON’s induction heater control board gives real-time process monitoring. You can see temperatures, power, voltage, and more. The system warns you if something is not safe.

Some important features are:

Real-time checks on inside temperatures and pressures.

Data collection with thousands of samples for each channel.

Saving all data for easy tracking and study.

Remote operation and logging using RS485 or other protocols.

With these tools, you can find problems early and plan repairs before things get worse. Real-time monitoring also makes power better, which keeps your system steady and lowers bad products.

Modern systems need to connect with other machines. JONSON’s induction heating control board works with many communication protocols, like RS485, Modbus RTU, and Modbus TCP. This lets you connect your control panel to your factory network or remote monitoring.

You can:

Change settings from far away.

Collect data for study.

Connect with other machines for smooth work.

JONSON has many models for different needs. For example, the 8kw, 380v model is good for big industrial heating jobs. Each model has a digital processing platform and easy power control. You get fast heating, steady work, and simple control for any job.

Tip: Pick a control board with good connectivity and diagnostics. This will help your system work its best.

You want your induction heater circuit to be fast and steady. Solid-state inverters help make this happen. These inverters turn electrical energy into the right kind for heating. You get high efficiency and save energy. The design is small, so you need less space. Digital integrated circuits make the system simple and reliable. You also stay safe because there is no high voltage at the output. Solid-state inverters work with many frequencies, from 0.1 to 500kHz. This means you can use your induction heater circuit for many different jobs.

Advantage | Description |

|---|---|

Efficiency | High inverter conversion efficiency, leading to energy savings. |

Compactness | The design is compact, saving 66% to 84% space compared to traditional valve equipment. |

Advanced Control Features | Utilizes digital integrated circuits for simplified design and improved reliability. |

Safety | High security with no high voltage at the output end, ensuring safe operation. |

Wide Frequency Range | Operates across a wide frequency range from 0.1 to 500kHz, suitable for various applications. |

Solid-state inverters keep your induction heater circuit steady. You get a quick response when the load changes. These inverters work with low resistance coils and adjust to new frequencies. Your heating stays efficient, even if your process changes.

You need sensors that are very accurate in your induction heater circuit. Precision sensors check temperature and other important things. These sensors help you control the heating process. You get fast feedback, so your system can react quickly. This keeps your results steady and safe. JONSON uses sensors that fit many types of induction heater circuit setups. You can trust your readings and make smart choices for your work.

Microcontrollers give you more control over your induction heater circuit. You can change heating settings for different jobs. Microcontrollers let you adjust frequency and temperature. You can use your system for metal work, plastic molding, or other needs. You also get system monitoring and easy ways to talk to other machines. Microcontrollers help you connect your induction heater circuit to fieldbus systems like EtherCAT. You can change output stages and keep your process running well.

Microcontrollers help with temperature control and system checks.

You can match inductors to output stages.

Communication features help you link with other systems.

You want your induction heater circuit to stay current. Firmware upgrades make this simple. You can add new features or make it work better. Upgrades help your system use new sensors or inverter designs. You keep your induction heater circuit ready for new jobs and changes. JONSON gives firmware support, so your system stays modern and reliable.

Tip: Pick an induction heater circuit with solid-state inverters, precision sensors, and microcontroller integration. You get steady work, fast response, and easy upgrades for every job.

You want your induction heater to be safe and last long. Good control boards use strong parts and smart design. Makers test each board to meet strict rules. This means the product works well in hard places like factories. Good build standards help your system work every day. You can trust your equipment to handle tough jobs without breaking.

Your equipment must handle heat, dust, and shaking. Durable boards have strong circuit paths and tough connectors. Special coatings protect the board from water and chemicals. You will need fewer repairs and have less downtime. Picking a durable board saves you money over time. Your system keeps working even in rough places.

Tip: Pick boards with extra shields against heat and water. This helps your system last longer.

Safety is important in every factory. You should check for key certifications before buying a control board. These show the product meets safety rules and keeps your team safe.

Certification Type | Description |

|---|---|

UL 508A | Standard for control panels, making sure they are safe from fire and other dangers. |

UL Listed | Shows the product was tested and meets safety rules. |

UL Recognized | Shows the product was checked for some uses but may not meet all rules. |

UL 508A is very important for control boards in factories.

It proves the board follows safety rules and lowers risk for companies.

Knowing the difference between UL Listed and UL Recognized helps you understand what you need.

You feel better when your control board has the right certifications. This means your equipment follows safety rules and helps stop accidents.

You want to save energy and spend less money. A high-performance induction heater control board helps you do this. Many factories save between 25% and 40% on energy. They see these savings after using advanced control boards. Smart power management and exact temperature settings make this possible. You use less electricity and waste less energy. This is good for your company and the planet.

Third-party audits show 25-40% energy savings.

Your business pays less for electricity.

Less heat is lost, and resources are used better.

You need your products to be made with the right heat. The right control board gives you this accuracy. It controls power, checks temperature, and lets you set heating times. You get the same results every time you use it. The table below explains how these features work together:

Aspect | Description |

|---|---|

Power Regulation | The board controls power for the right frequency, voltage, and current. |

Temperature Control | Sensors watch and change output to keep the right temperature. |

Heating Time Control | You can set heating times or use profiles for steady work. |

Safety Features | Safety checks and monitoring keep your equipment and team safe. |

You can count on your system to give the same results each time.

You want a system that is simple and safe to use. Advanced induction heater control boards have many easy features. Workers say heating is faster and there is less maintenance. You can change settings for each job. Safety features like automatic shut-off and overheat protection keep everyone safe.

Automatic shut-off and overheat protection help keep people safe.

Less maintenance is needed because of new technology.

Energy efficiency lowers costs and helps the environment.

Exact temperature control stops damage to materials.

Fast heating makes work go quicker.

You can change settings for different heating jobs.

You need a solution that works in many places. JONSON’s induction heater control board fits many jobs, from factories to food processing. The table below shows where you can use these boards:

Industrial Sector | Description |

|---|---|

Heating | Used for many heating jobs, showing it can adapt. |

Chemical Industry | Helps with jobs that need exact heating control. |

Mold Manufacturing | Supports heating when making molds. |

Plastic Machinery | Makes plastic processing work better. |

Food Processing | Keeps food heating safe and efficient. |

You get a digital system that you can program. The open design lets you use it for many tasks.

You want to choose the best induction heater control board. First, check the most important features. Use this table to help you compare:

Feature | Description |

|---|---|

Voltage and Power Requirements | Make sure your board fits the power and voltage you need. |

Multi-Zone Management | Pick a board that can control more than one heating zone. |

High-Limit Controllers | Find safety controls that stop overheating and need a reset. |

Safety and Monitoring Features | Choose a board with alarms and lights for safety and system checks. |

You should also look for extra safety parts like:

Temperature sensors

Current sensors

Circuit breakers

Emergency stop buttons

The control panel lets you change and watch power, frequency, and temperature. You get updates right away about how your system is working.

You need to look at different boards before you buy one. Think about cost, how long it lasts, and how easy it is to fix or swap. This table shows the main points:

Factor | Repair | Replacement |

|---|---|---|

Cost | Repairs cost less at first, but it depends on the damage. | New boards cost more, but you get a warranty. |

Long-Term Reliability | Repairs might not last. | New boards last longer and have a warranty. |

Downtime | Repairs take longer if parts are hard to find. | Replacing is faster and gets you back to work. |

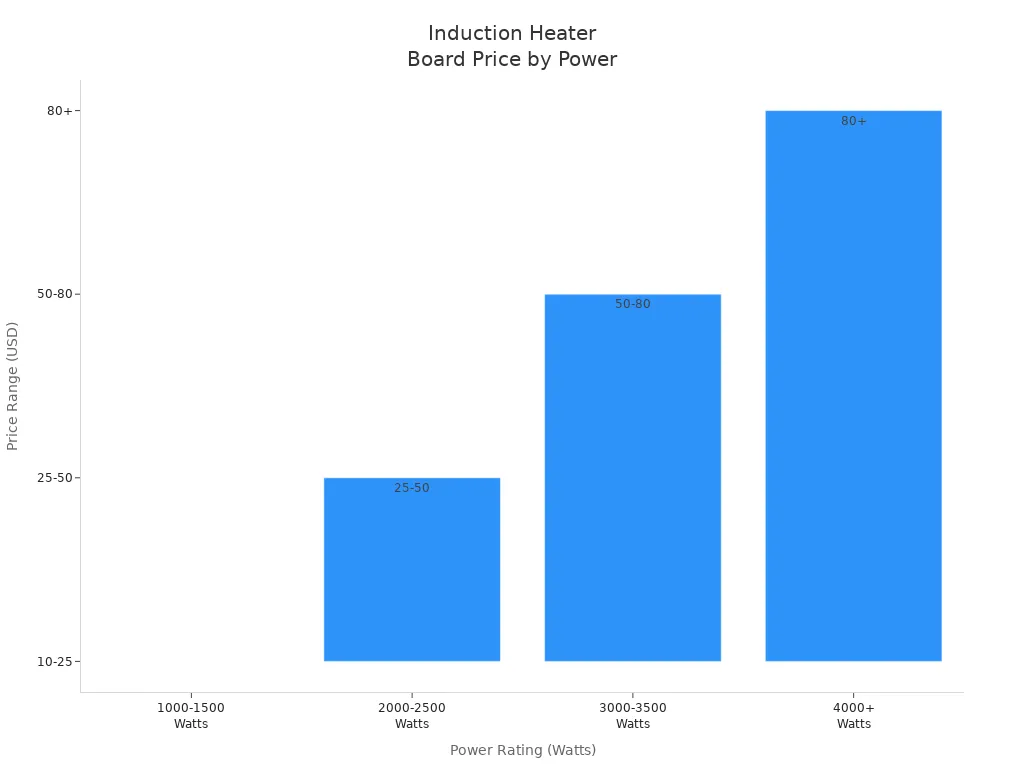

You should also look at prices by power rating. See the chart below:

Boards with more power cost more money. They also have more parts and better ways to handle heat.

Experts say you should follow these steps when picking a board:

Know what materials you will heat. Different things need different settings.

Think about your job, like brazing or annealing. Each job needs special power and frequency.

Decide if you need a heater that stays in one place or one you can move. Your workspace helps you choose.

Tip: Always pick a control board that matches your power and safety needs. This helps you control your system and keeps it working well.

You can make your work better with a high-performance induction heater control board. It helps your system use less energy and stay safe. Your machines will also work well for a long time. If you pick a trusted supplier like JONSON, you get many good things. You get fast and even heating with electromagnetic induction heating. You lose less heat and use less energy, so your system lasts longer. Smart temperature control keeps your results the same every time. The board is strong and made for tough jobs in factories. Choosing a control board with good technology and strong support is a smart choice.