Views: 0 Author: 周武江 Publish Time: 2026-01-28 Origin: Site

In the current environment of increasingly fierce competition in the manufacturing industry and continuously rising energy costs, "energy-saving transformation" is no longer the patent of large factories.

More and more small and medium-sized factories are discovering:

Profit is gradually consumed by electricity bills, but equipment cannot be stopped;

I want to upgrade, but I am worried about the high investment, slow results, and high risks.

Among numerous energy-saving solutions, variable frequency induction heating furnaces are gradually becoming a practical choice for small and medium-sized factories to upgrade their heating systems, with controllable investment, fast results, and low risks.

In industries such as plastics, rubber, food, chemicals, and hardware, small and medium-sized factories commonly face the following problems:

Traditional resistance heating and gas heating equipment operate at full power for a long time, regardless of whether they really need so much heat, resulting in high electricity bills.

Heating fluctuates rapidly, with noticeable temperature fluctuations,

Resulting in unstable product quality and high rework rate.

3.Fast aging of equipment and high maintenance costs

Frequent start stop and high surge current,

The service life of vulnerable parts such as heating tubes and contactors is short.

4.I want to upgrade, but I'm afraid the renovation will be complicated

Many small and medium-sized factories are concerned about:

Should we stop production?

Do you want to change the pipeline?

Can employees use it?

Simply put, in plain language:

Variable frequency induction heating furnace uses "adjustable electromagnetic induction method" to heat, only giving you the energy you really need.

It's not 'full power as soon as it's turned on', but rather:

Initial heating stage: high power, fast heating up

Approaching the target temperature: automatic power reduction

Constant temperature stage: maintain temperature with minimal energy consumption

For small and medium-sized factories, this' on-demand heating 'is crucial.

Compared with traditional heating methods, the core energy-saving logic of variable frequency induction heating furnaces is:

Do not perform 'ineffective heating'

Infrequent full load impact

Not relying on repeated start stop temperature control

In actual working conditions, the common energy-saving range for small and medium-sized factories is 15% -30%,

The more complex and fluctuating the heating conditions, the more obvious the energy-saving effect.

Variable frequency control makes the induction heating process "controllable and repeatable":

Adjustable heating speed

Temperature curve can be set

Long term constant temperature without fluctuation

This is particularly important for the following applications:

Plastic extrusion, injection molding machine heating

Heating of chemical reaction kettle

Food steaming, cooking, and insulation

Metal preheating and heat treatment

Stability is often more valuable than 'fast'

The common problems with traditional non variable frequency equipment are:

High starting current

Strong thermal shock

Long term 'hard carrying' of electronic components

And the variable frequency induction heating furnace has:

soft start

Stable current

Low thermal shock

Not only does the heating equipment have a longer lifespan,

It is also more friendly to the factory's transformers and power grid system.

This is the most practical concern for many bosses.

Flexible transformation does not necessarily require a 'big fight'

Variable frequency induction heating furnace can:

modular installation

Partial replacement of the original heating section

Run in parallel with the original system

In most cases, there is no need to shut down the entire production or start over from scratch.

Easy to operate, without relying on "master craftsmen"

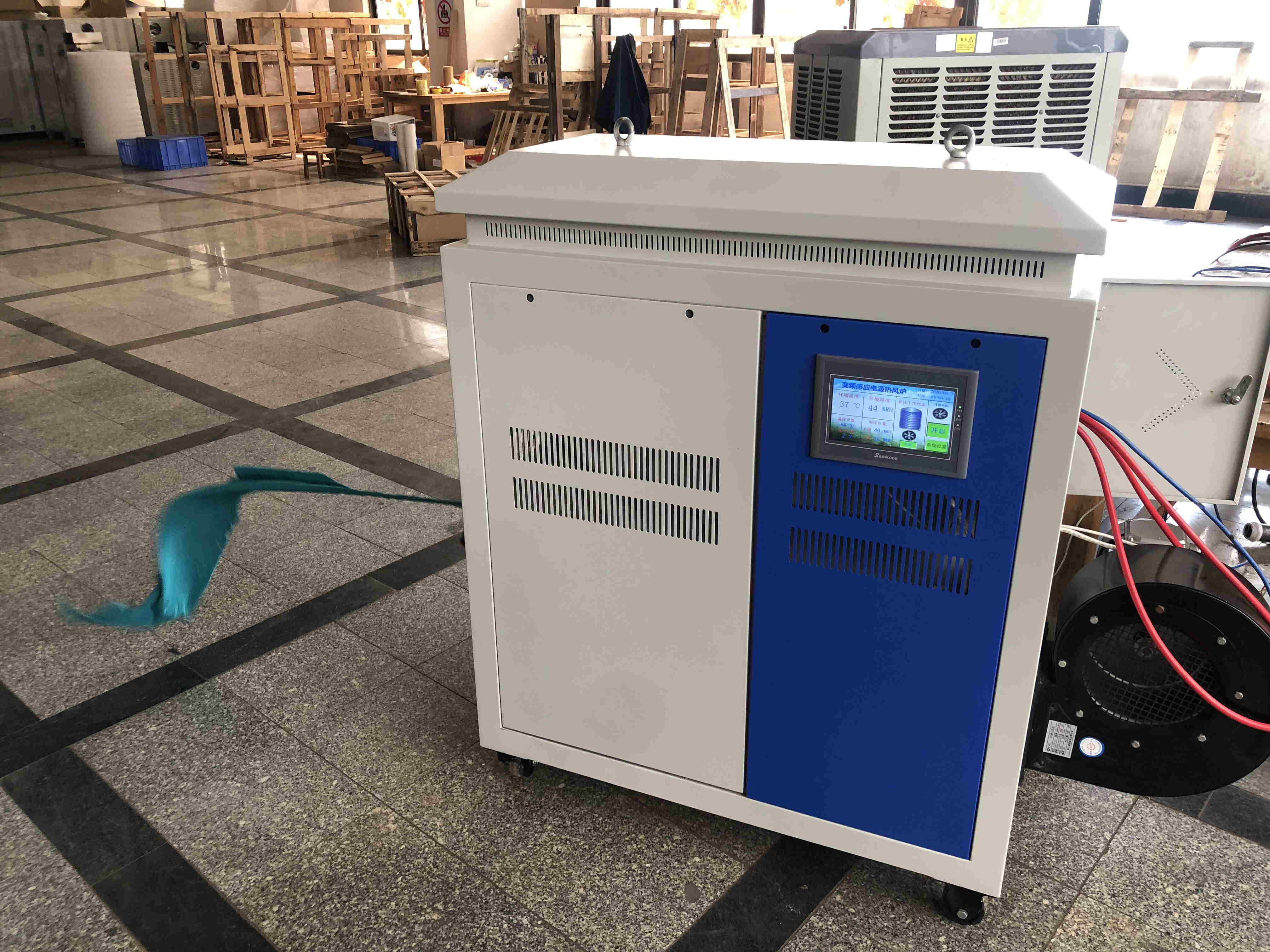

Modern variable frequency induction heating furnaces typically have:

One-key start

Automatic temperature control

Parameter visualization

Ordinary operators can get started with simple training.

If you meet any of the following criteria, the variable frequency induction heating furnace is worthy of careful evaluation:

High proportion of electricity bills in costs

Long heating time and frequent operation

There are requirements for temperature stability

Equipment is old and frequently maintained

There are energy-saving renovation indicators or pressures

For small and medium-sized factories,

Energy saving renovation is not about pursuing advanced technology, but about solving practical problems.

The value of variable frequency induction heating furnace lies in:

Relatively controllable investment

Clear return cycle

Risk assessable

The effect can be quantified

It is not a conceptual solution, but a practical solution that has been validated by numerous factories.

In today's world where energy costs continue to rise,

Reducing ineffective energy consumption as soon as possible is to leave an extra way for the enterprise to survive.