JX

jiangxin/Jonson

| Availability: | |

|---|---|

| Quantity: | |

Our electromagnetic induction heating coils are engineered to deliver precise, efficient heating solutions across a diverse range of industrial and commercial applications. Leveraging advanced electromagnetic induction technology, these coils enable rapid, uniform heating while minimizing energy waste, catering to the evolving needs of modern production processes.

Special - Shaped Surface Heating: Available for drum - type frying pans, upturned cookers, curved surfaces like rollers, and irregular - shaped heating. Whether it's the arc - shaped heating of a roller or the unique contour of an irregular component, our coils ensure consistent heat distribution. Compared with competing products, which may struggle with heat uniformity on complex shapes, our design optimizes magnetic field distribution to adapt to diverse geometries.

Flat - Surface Heating: The disc - shaped flat - surface coils are ideal for equipment requiring planar heating. In contrast to some rivals' flat coils that might have edge - heating inefficiencies, our coils provide balanced heating across the entire flat area, suitable for tasks from simple metal sheet heating to precise food processing like pancake griddles.

Teppanyaki and Pancake - Making: Specially designed for teppanyaki grills and pancake machines. While competing coils may not be tailored to the rapid - heating and temperature - retention needs of food service, our coils ensure quick heat - up for immediate cooking and stable temperatures to maintain food quality, enhancing the efficiency of catering operations.

Semi - Circular and Cylindrical Containers: For semi - circular woks, soup buckets, and other hemispherical or cylindrical vessels. Unlike some competitors' one - size - fits - all approach, our coils are custom - engineered to match the exact curvature of these containers, ensuring heat penetrates evenly from the sidewalls to the center, crucial for processes like uniform soup heating or material melting in cylindrical tanks.

Oil Drum and Tank Heating: Designed for heat treatment of oil drums and electromagnetic heating of oil tanks. Competing products may lack the power - regulation precision for large - volume heating. Our coils can be adjusted to deliver the right amount of heat, preventing over - heating or uneven heating in large oil - storage vessels, ensuring safe and efficient pre - heating or maintenance heating.

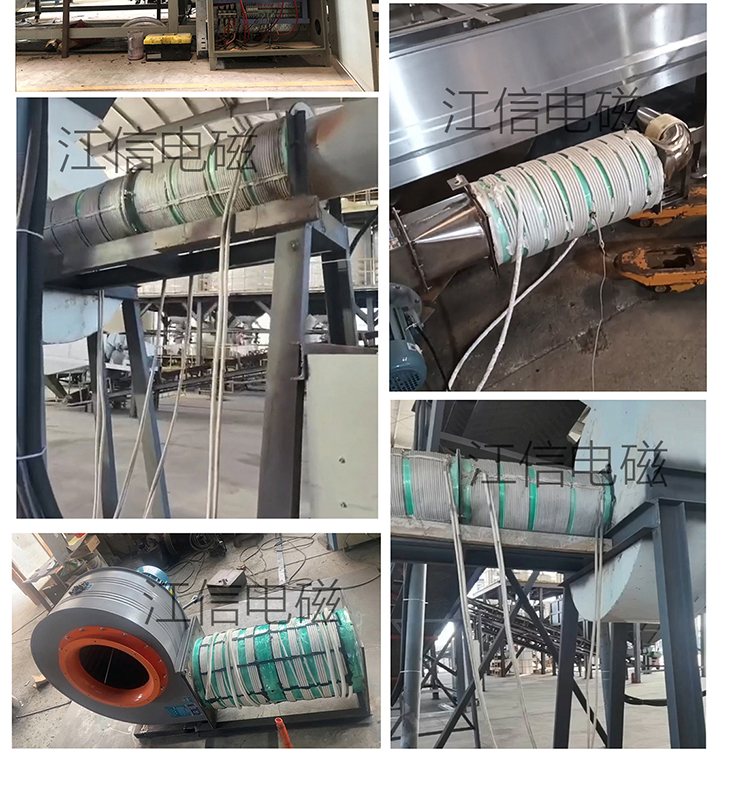

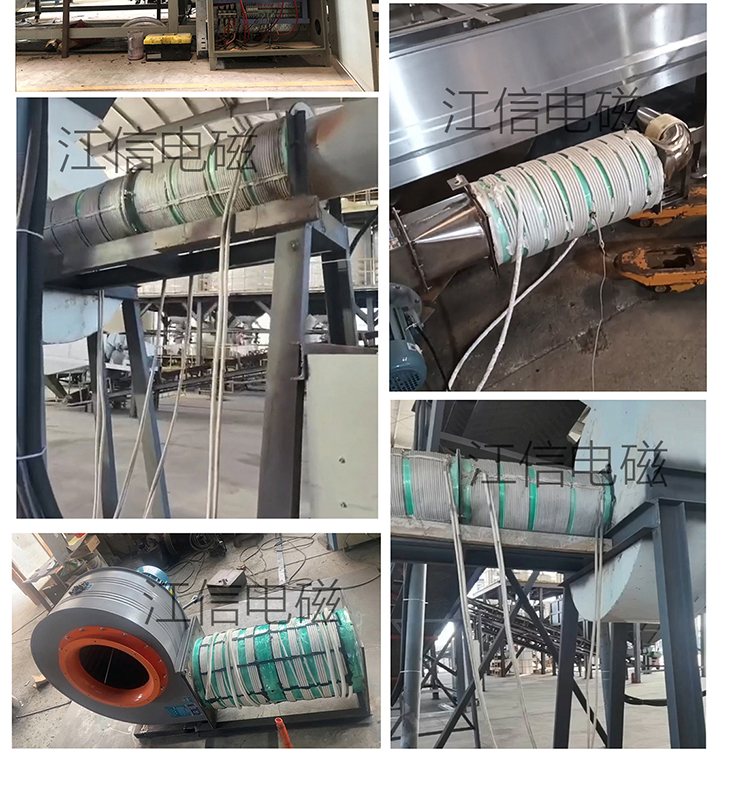

Pipeline Heating: Suitable for steam secondary heating, heating of heat - conducting oil, water passing, hot - air heating, etc. In comparison to rival pipeline coils that may cause pressure drops or inconsistent heating along the pipeline, our coils are designed with optimized winding to ensure smooth fluid flow while achieving uniform heating, maximizing the utilization of thermal energy in fluid - handling systems.

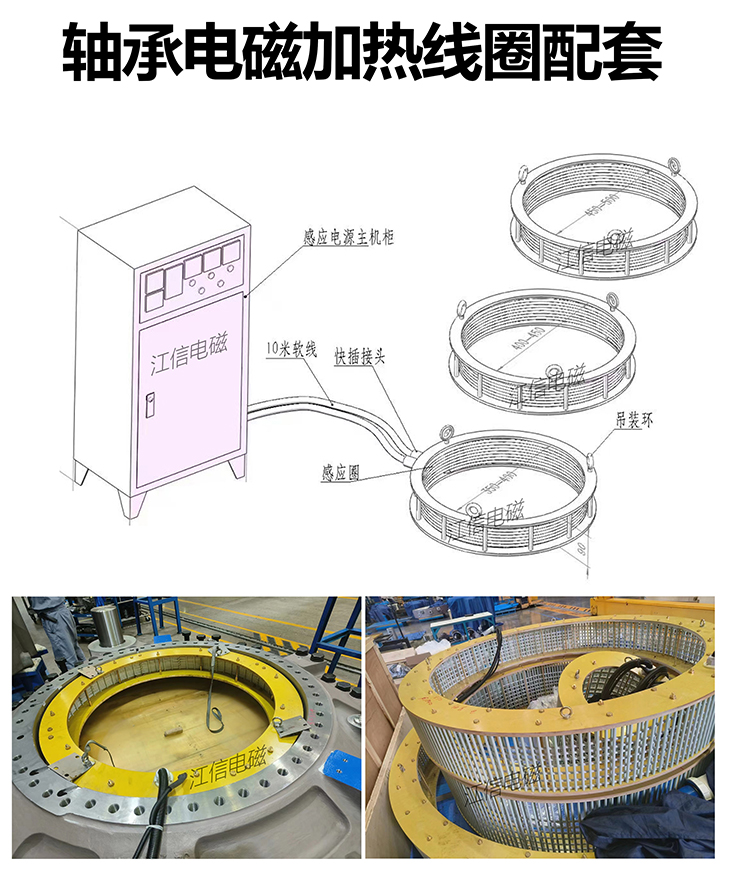

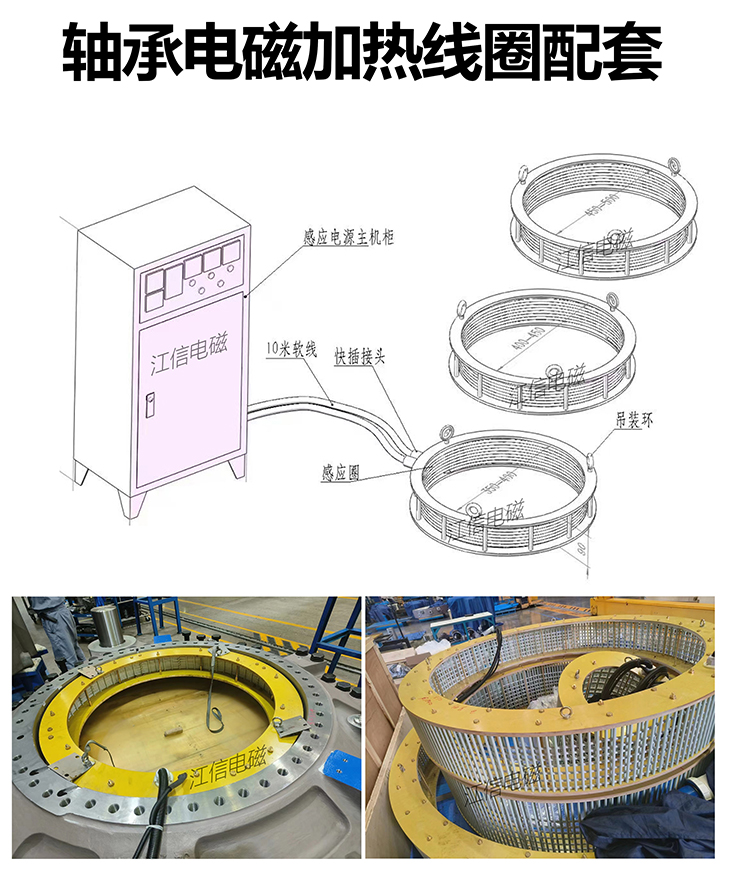

Bearing Heating: Packages for bearing electromagnetic heating during installation. Unlike some competing solutions that may risk over - heating bearings and damaging components, our coils use precise magnetic - field control to heat bearings to the exact expansion temperature needed for easy installation, reducing equipment - maintenance risks.

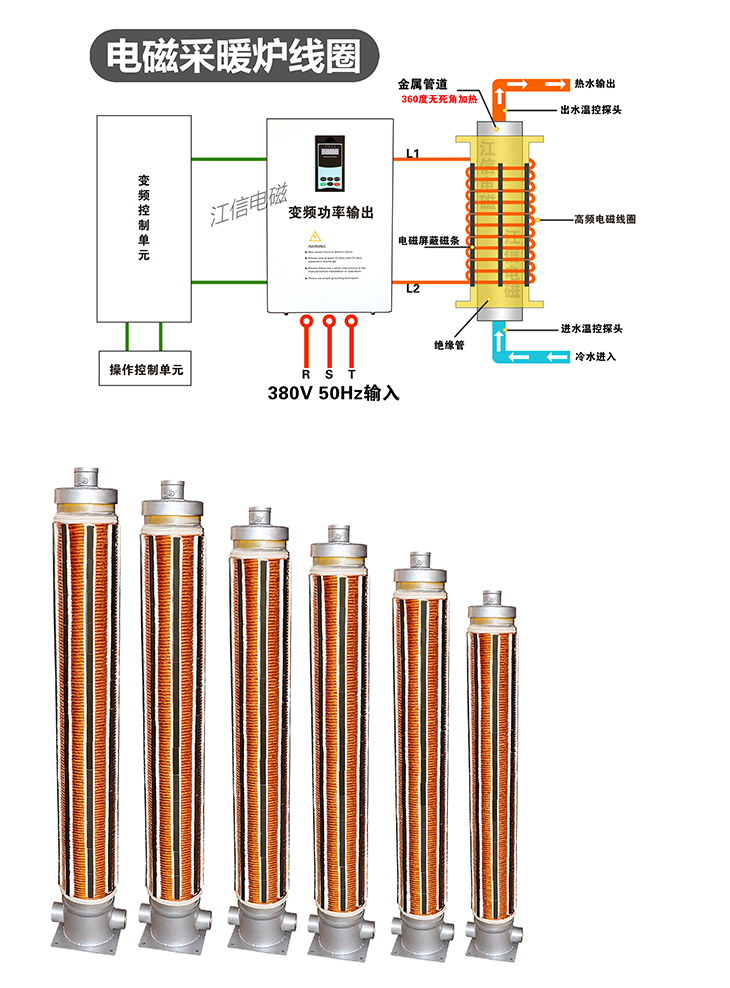

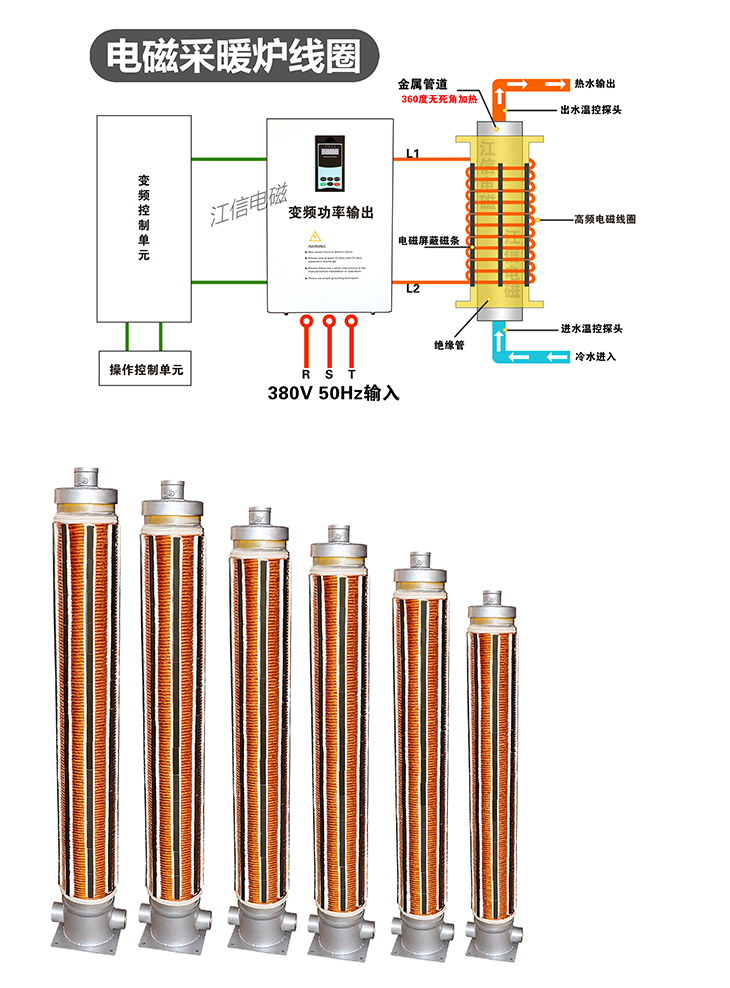

Electromagnetic Heating - for - Heating - Boiler Coils: adaptation heating - for - heating - boiler systems. Compared with competitors' coils that might have lower energy - conversion rates, our coils convert electrical energy to thermal energy efficiently, helping to reduce operating costs for heating - supply systems.

Our electromagnetic induction heating coils are engineered to deliver precise, efficient heating solutions across a diverse range of industrial and commercial applications. Leveraging advanced electromagnetic induction technology, these coils enable rapid, uniform heating while minimizing energy waste, catering to the evolving needs of modern production processes.

Special - Shaped Surface Heating: Available for drum - type frying pans, upturned cookers, curved surfaces like rollers, and irregular - shaped heating. Whether it's the arc - shaped heating of a roller or the unique contour of an irregular component, our coils ensure consistent heat distribution. Compared with competing products, which may struggle with heat uniformity on complex shapes, our design optimizes magnetic field distribution to adapt to diverse geometries.

Flat - Surface Heating: The disc - shaped flat - surface coils are ideal for equipment requiring planar heating. In contrast to some rivals' flat coils that might have edge - heating inefficiencies, our coils provide balanced heating across the entire flat area, suitable for tasks from simple metal sheet heating to precise food processing like pancake griddles.

Teppanyaki and Pancake - Making: Specially designed for teppanyaki grills and pancake machines. While competing coils may not be tailored to the rapid - heating and temperature - retention needs of food service, our coils ensure quick heat - up for immediate cooking and stable temperatures to maintain food quality, enhancing the efficiency of catering operations.

Semi - Circular and Cylindrical Containers: For semi - circular woks, soup buckets, and other hemispherical or cylindrical vessels. Unlike some competitors' one - size - fits - all approach, our coils are custom - engineered to match the exact curvature of these containers, ensuring heat penetrates evenly from the sidewalls to the center, crucial for processes like uniform soup heating or material melting in cylindrical tanks.

Oil Drum and Tank Heating: Designed for heat treatment of oil drums and electromagnetic heating of oil tanks. Competing products may lack the power - regulation precision for large - volume heating. Our coils can be adjusted to deliver the right amount of heat, preventing over - heating or uneven heating in large oil - storage vessels, ensuring safe and efficient pre - heating or maintenance heating.

Pipeline Heating: Suitable for steam secondary heating, heating of heat - conducting oil, water passing, hot - air heating, etc. In comparison to rival pipeline coils that may cause pressure drops or inconsistent heating along the pipeline, our coils are designed with optimized winding to ensure smooth fluid flow while achieving uniform heating, maximizing the utilization of thermal energy in fluid - handling systems.

Bearing Heating: Packages for bearing electromagnetic heating during installation. Unlike some competing solutions that may risk over - heating bearings and damaging components, our coils use precise magnetic - field control to heat bearings to the exact expansion temperature needed for easy installation, reducing equipment - maintenance risks.

Electromagnetic Heating - for - Heating - Boiler Coils: adaptation heating - for - heating - boiler systems. Compared with competitors' coils that might have lower energy - conversion rates, our coils convert electrical energy to thermal energy efficiently, helping to reduce operating costs for heating - supply systems.

content is empty!